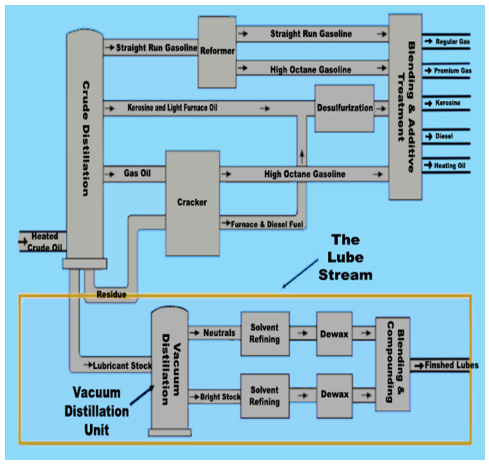

Vacuum Distillation

- At atmospheric pressure, the temperature required to boil the lube fraction (1000°F) is high enough to damage or “crack” oil molecules.

- Thermally cracked material results in product quality problems and operating problems in the atmospheric distillation unit.

- Under a vacuum, boiling temperatures are reduced to a safe level while oils can be vaporized without thermal cracking.

- Vacuum distillation is used to separate lube oil fractions or “cuts”.

- Additional processes (deasphalting, dewaxing & solvent extraction) yield finished base oils.

- The lube stream produces several Neutral “cuts” and one Bright Stock “cut”.

#LydenOilSchool